Reel cables play a vital role in modern industrial and mobile installations, connecting moving equipment to power, control, or data systems while allowing cables to be extended and retracted safely. Whether used in factories, construction sites, offshore platforms, or entertainment setups, the correct selection of a reel cable determines both performance and safety.

Choosing a suitable reel cable is not just about picking the right length. It requires understanding mechanical stress, bending radius, current capacity, environmental exposure, and reel type. A poor match can result in cable damage, signal interference, safety hazards, and costly downtime.

This comprehensive guide explains the key considerations when selecting a reel cable for your installation — including cable structure, materials, reel mechanisms, environmental factors, and maintenance practices.

A reel cable is a flexible electrical or communication cable designed to be wound onto and unwound from a reel or drum. This allows it to move with mobile machinery, traveling cranes, hoists, vehicles, or temporary power systems while maintaining continuous power or data transmission.

The key advantage of reel cables is mobility with protection. Unlike fixed cables, reel cables experience constant flexing and require a design that resists mechanical wear, torsion, and environmental stress.

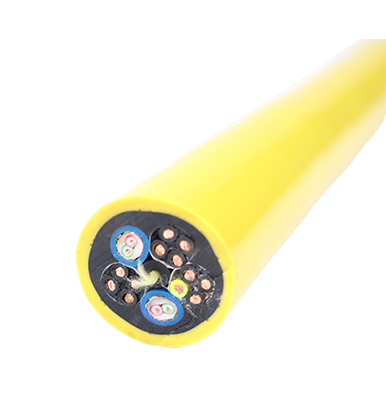

Reel cables have a specialized structure to withstand frequent movement:

Conductor: Typically made from fine-stranded copper for maximum flexibility and low electrical resistance.

Insulation: Protects conductors and prevents short circuits. Common materials include rubber, thermoplastic, or polyurethane.

Filler: Keeps internal structure stable during coiling and uncoiling.

Shielding (optional): Prevents electromagnetic interference for data or control lines.

Outer Jacket: Provides protection against abrasion, oil, water, and UV exposure — often made from PVC, rubber, or polyurethane.

This layered design ensures that the cable performs reliably even after thousands of flexing cycles.

Unlike stationary cables, reel cables experience dynamic stress every time they wind or unwind. The movement involves bending, torsion, and sometimes tension. The key mechanical factors to consider are:

Every cable has a minimum bending radius, defined as the smallest curve it can safely bend without damaging internal conductors. For reel cables, maintaining a proper radius is essential to prevent conductor fatigue or insulation cracking.

The cable should not be stretched beyond its tensile strength. When the reel retracts, improper tension control can lead to mechanical stress or connector damage.

Reel cables used on rotating or oscillating reels face twisting forces. Specialized construction with layered stranding helps resist torsional strain.

Different installations require different reel cable characteristics. The following are common use scenarios:

Used on cranes, hoists, robotic arms, and moving conveyors. These cables must endure repetitive bending and sometimes chemical exposure.

Used for mobile power distribution, lighting, and temporary installations. Cables must be rugged, weather-resistant, and easy to deploy.

In marine environments, reel cables must resist corrosion, moisture, and UV degradation while maintaining flexibility in cold or humid conditions.

Used for lighting and audio setups where long cable runs are extended and retracted frequently. Flexibility and tangle resistance are key.

Cables operate under mechanical load, abrasion, and dust. Reinforced jackets and high-impact resistance are required.

The outer jacket material largely determines durability, flexibility, and environmental protection. The most common materials include:

Affordable and easy to handle

Suitable for indoor and light-duty applications

Moderate resistance to heat and abrasion

Can stiffen in cold conditions

Excellent flexibility and shock resistance

Performs well under mechanical stress

Good electrical insulation

Heavier and more expensive than PVC

High abrasion and oil resistance

Remains flexible in extreme temperatures

Resistant to UV and moisture

Ideal for demanding outdoor or industrial use

Selecting the right jacket depends on your environment and motion frequency.

A reel cable’s performance is defined by its electrical properties, which should match the system’s requirements:

Ensure the cable’s rated voltage meets or exceeds the supply voltage to avoid insulation failure.

Select a conductor cross-section large enough to handle continuous load without overheating.

If the cable transmits data or control signals, shielding may be required to prevent electromagnetic interference.

For long cable runs, low resistance and controlled capacitance help maintain efficiency and prevent signal loss.

Environmental exposure has a major impact on reel cable life and safety. Evaluate the following before installation:

Extreme heat can soften insulation, while cold can make cables brittle. Choose materials rated for your operating temperature range.

Outdoor and industrial installations may expose cables to water, oil, or chemicals. Look for cables with appropriate resistance ratings.

Cables used outdoors or in marine conditions should have UV-resistant jackets to prevent cracking or discoloration.

Heavy-duty environments require reinforced jackets or additional protective sheathing.

Choosing the correct reel type is as important as selecting the right cable. Reel designs include:

Use a spring mechanism to retract cables automatically. Ideal for shorter lengths and light-duty applications.

Use electric or hydraulic motors for controlled retraction. Common in industrial systems with heavy or long cables.

Operate via hand cranks or handles — practical for portable setups.

The reel’s diameter, core size, and tension system must match the cable’s bending radius and weight. Incorrect pairing can shorten cable life significantly.

Proper installation ensures performance and safety:

Verify Bending Radius: Install with gentle curves, never sharp bends.

Align Reel and Equipment Movement: The cable should move smoothly without cross-over or twisting.

Use Guide Rollers or Cable Layering Systems: Prevent uneven winding.

Secure Connections: Avoid stress on terminals and connectors.

Test Before Full Operation: Check continuity and insulation resistance.

Electrical safety is critical in any reel cable installation:

Ensure cables meet local electrical and fire safety standards.

Avoid exceeding rated voltage or current.

Use proper grounding where required.

Keep reel cables away from sharp edges and moving machine parts.

Inspect regularly for damage, burns, or exposed conductors.

A damaged cable can lead to electrical shocks, short circuits, or fires — all preventable with proper selection and inspection.

Routine maintenance extends cable life and prevents unexpected failures.

Inspect for cracks, cuts, or frayed insulation. Replace damaged sections immediately.

For motorized or spring reels, ensure smooth retraction and tension balance.

Wipe off dust, oil, or corrosive substances that could degrade the outer jacket.

Measure continuity and insulation resistance periodically to detect hidden faults.

Even with proper use, issues may occur:

Cable twisting: Caused by misalignment between reel and equipment motion.

Uneven winding: Usually results from worn guides or improper tension.

Overheating: May indicate undersized conductors or high ambient temperature.

Connector damage: Often due to pulling on cables instead of plugs.

Addressing these early prevents costly downtime.

Balancing cost and reliability is key. While budget-friendly cables might seem attractive, they often lead to higher replacement and maintenance costs.

Investing in a cable that matches operational demands ensures better safety and long-term savings. Consider total cost of ownership — including installation labor, downtime, and energy loss — rather than just purchase price.

Sustainability in cabling is becoming increasingly important. Opt for cables that use recyclable materials or comply with environmental standards. Proper disposal and recycling reduce waste and prevent harmful chemical release.

Selecting durable cables also supports sustainability by minimizing replacement frequency and resource use.

Emerging innovations focus on:

Smart monitoring: Built-in sensors to detect bending stress or temperature.

Lightweight composite jackets: For higher flexibility and reduced wear.

Environmentally friendly insulation: Non-halogen and recyclable compounds.

Improved shielding: To support higher data transmission speeds.

These trends enhance both safety and performance across industries.

Choosing the right reel cable for your installation requires careful evaluation of electrical, mechanical, and environmental factors. The ideal cable should offer:

The correct voltage and current rating

Adequate flexibility and bending radius

Resistance to temperature, chemicals, and abrasion

Compatibility with the chosen reel system

Compliance with safety and quality standards

A well-chosen reel cable ensures stable operation, reduces maintenance costs, and improves safety. Understanding your specific application environment — from motion type to exposure conditions — is the foundation of a successful installation.

Bu web sitesi, web sitemizde en iyi deneyimi yaşamanızı sağlamak için çerezleri kullanır.

Yorum

(0)